Protecting High-Value Electronic and Aerospace Components

The aerospace industry requires high-value component protection at all states of the supply chain. The design, development, and production of parts for spacecraft and aircraft systems that operate on the edges or outside of the earth’s atmosphere is a rapidly evolving industry that demands secure transportation of aerospace parts and assemblies.

Hazards of Aerospace Component Handling and Shipping

Due to the delicate nature of electronic components and the high value of components, there are many hazards that need to be mitigated or eliminated during transport and storage of aerospace parts. Protective packaging for electronics must meet aerospace packing standards by protecting components from:

- Static charge buildup

- Electrical shocks

- Vibrations

- Extreme temperatures

- High humidity

- Magnetic exposure

- Moisture or fluid leaks

- Physical damage from dropping or crushing

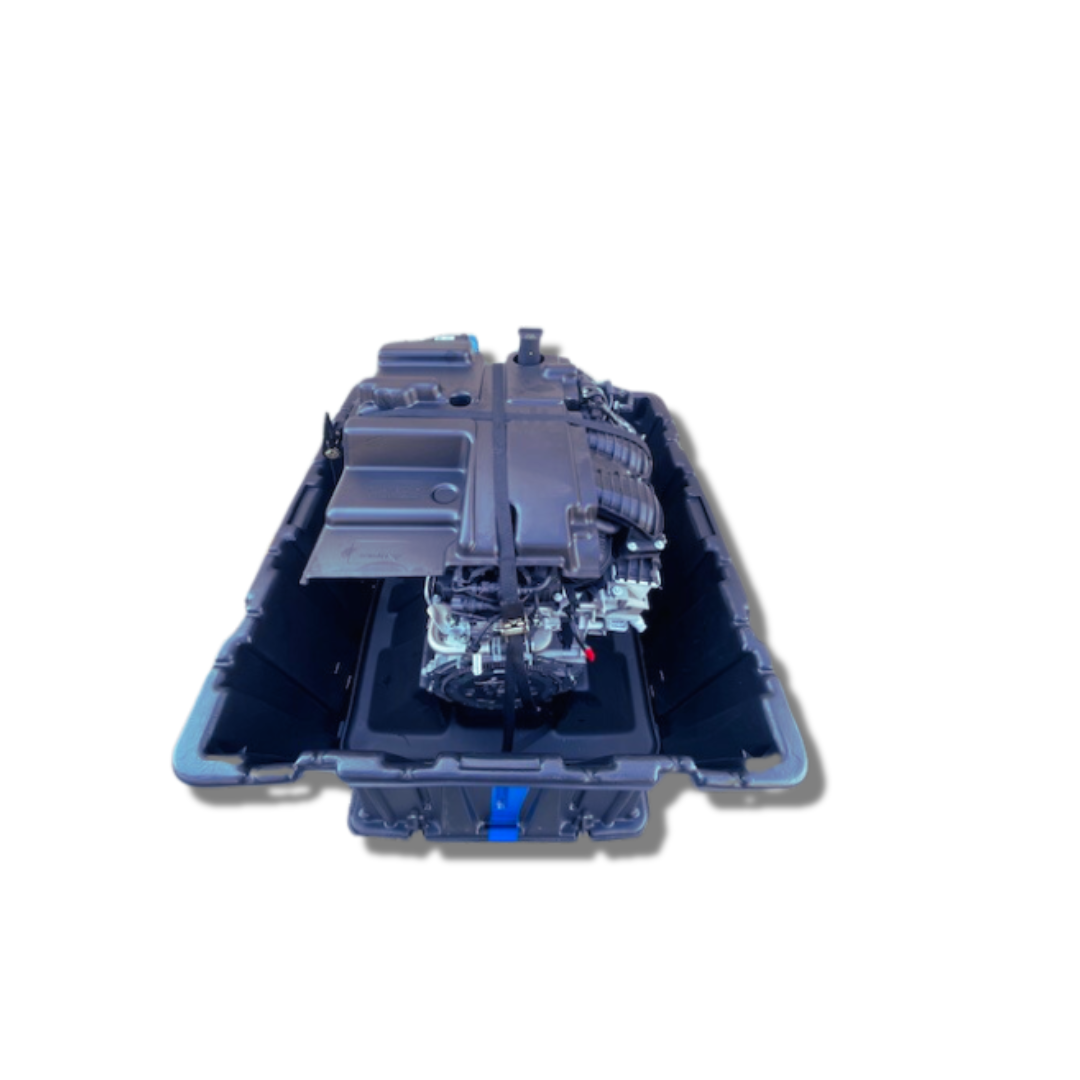

Custom Protective Containers for the Aerospace Industry

Not only do aerospace and aeronautical parts have a high value that can be lost during storage, but any unseen damage can directly impact aerospace component safety and performance. When the lives of pilots and astronauts are on the line, reliable electronic component handling and protection is of vital importance.

For high volume production parts, antistatic containers for electronics can be ready reusable transport containers that meet stringent aerospace safety standards. For new designs, prototypes, and testing cycles during development, a custom formed container may be the key to high-value component protection during transport and storage.

During development and production phases of aerospace engineering, static-free and impact-resistant material handling bins and trays may also be required for aerospace component safety during assembly and disassembly. At all stages of development and manufacturing, aerospace electronic component handling processes must maintain the integrity of advanced engineering and data for quality control.

Advanced Material Handling Solutions for the Industry

In research areas and during manufacturing production, material handling containers are used to temporarily store components needed for assembly. These containers must also be anti-static and protect the high value contents from hazards that would damage them. Common material handling containers include:

- Totes

- Boxes

- Trays

- Dividers

- Picking bins

The same requirements that apply to aerospace shipping containers should also be followed when looking for durable aerospace storage solutions and material handling containers. At every step in the process of the secure transportation of aerospace parts or during storage and handling, Endural containers meet the standards and custom specifications of the most demanding aerospace applications.

Endural Provides Custom Component Containers for Aerospace Applications

Endural has been providing custom and stock transport cases and material handling containers since 1960. We have options to function as black box transporters and reusable custom-formed shipping containers for high value component transportation, storage, and handling. Made of 100% recyclable materials, these reusable containers offer low environmental impact and superior component protection.

With years of experience working with defense and government contracts, Endural uses high-density polyethylene (HDPE) materials to create lightweight, stackable, and leak-resistant shipping and handling containers for the aerospace industry. Designed to meet all industry standards, Endural component-handling containers resist impacts and environmental stress

All aerospace cases, containers, boxes, and trays are available in ESD materials that are static dissipative and conductive. These materials protect the most sensitive electronic components that can be damaged from even small static discharges. Custom designs are fast and affordable to meet the needs of research and development or limited production runs.

Selecting or Designing the Right Aerospace Component Packaging

For high value component protection, the experts at Endural will work with you to help you choose the right stock option or custom design for your specific requirements. With the right containers for your application, you can:

- Reduce or eliminate component damage in transit.

- Add ESD materials or additional stiffness for more delicate parts.

- Design custom molded inserts that fit inside reusable HDPE cases for R&D.

- Safely store valuable parts and components in warehouses.

- Protect delicate components during production and testing phases.

Industry Experts for Your Aerospace Component Design and Production

In addition to years of experience in the field, Endural is focused on the complete supply chain life cycle, providing multiple benefits from the wide range of materials and designs we offer to our customers. Some of these include:

- Superior protection for high-value parts and equipment even in harsh environments and adverse conditions

- Cost-effective packaging, storage, and handling solutions that keep costs low while preventing loss during transport

- Custom options to fit any size part or component in the type of material and level of protection required for safe transport or storage

- Guaranteed compliance with your industry standards and regulations, including aerospace component safety standards