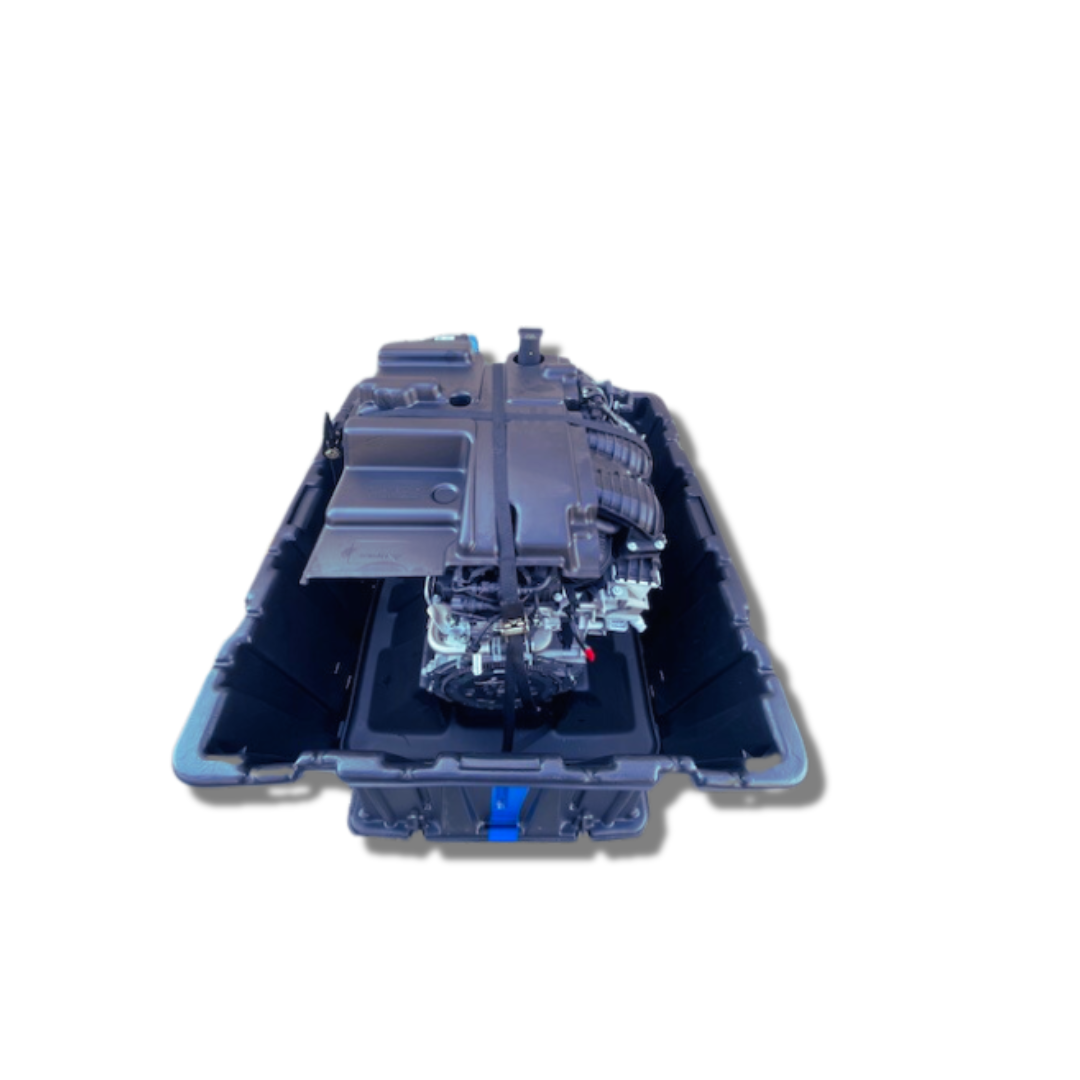

Engine Cases Protect Products During Transport

Engine Packaging Tips and Best Practices for Manufacturers

As engine packaging products have evolved over the years, reusable transportation cases are raising the bar for manufacturers of diesel and automotive engines. Every year, more and more OEMs and remanufacturing companies are making the shift from disposable cardboard and wood packaging to purpose-built, reusable, and recyclable engine shipping containers.

Industry Challenges with Engine Transportation

Engine cases made of wood or cardboard are often damaged in transit and can be crushed or fall when stacked in storage. Many manufacturers have simply accepted this loss of expensive products as a cost of doing business, but modern alternatives are available that allow safer transportation and storage of engines, transmissions, and other large mechanical components.

Using disposable packaging materials to transport engines also generates tons of waste materials each year. Some wooden containers and crates are being reused, but their integrity rapidly degrades with each use. It takes a large amount of employee time at the destination to break down and properly recycle disposable packaging materials. Most disposable materials used for engine packaging and transport end up in landfills.

These challenges are leading many manufacturers to switch to reusable transportation cases that protect the engine during transport, protect workers involved in handling, protect the environment with sustainable shipping solutions, and ultimately protect their bottom line.

The Benefits of Reusable HDPE Engine Shipping Cases

Making the switch to reusable engine cases allows the same high-quality protection of a vacuum-formed HDPE (High Density Polyethylene) to be reused over and over again. Endural’s engine transportation cases can be returned for reuse and retain their value. They are stackable, recyclable, and made with recycled materials.

Endural HDPE transportation cases are resistant to environmental extremes, crushing, impact damage, solvents, and most chemicals. They meet the quality standards in place for major automotive companies. Endural engine cases are chosen for their reliability and sustainability in today’s markets.

Endural also offers their entire line of ready made and custom containers in ESD materials that are static dissipative and conductive as required. With more than 50 years of experience in the industry, Endural can engineer, tool, and produce custom molded cases with replaceable inserts that change with your product line.

The Endural Advantage: Superior Protection and Sustainability

Using Endural cases is not only sustainable for the environment but sustainable for your bottom line. Switching to HDPE engine or component transportation cases from Endural offers these advantages to your business:

- Reliable and predictable costs for packaging do not fluctuate with the cost of wood or cardboard.

- Returnable shipping crates bring value back whether they are returned empty or with cores to be remanufactured or recycled.

- Long-lasting reliable engine cases offer superior protection to your products during transport and stand up to stacking and lifting equipment, making more use of warehouse space.

- Endural cases are not only resistant to chemicals and solvents, but meet the requirements of EV battery manufacturers for safely containing potentially dangerous materials.

- Custom designs and inserts will fit the engine perfectly, eliminating movement during transport while preventing crushing or compression of delicate parts enroute.

Learn More About Cost-Effective Transportation Cases from Endural

Once a valuable manufactured engine or product leaves your manufacturing facility, you have little control over the conditions and handling it will endure while in transport. Using a strong and form fitting shipping case from Endural will protect your engine during the packing, transportation, and handling process.

With thousands of HDPE transportation cases making millions of round trips, we have perfected the process and offer standard or custom-formed cases, as well as help in making the transition. Contact us today to learn more about how Endural can keep your budget in the black while promoting green solutions for your company’s future.