The Ultimate Solution for Safe and Secure EV Component Transport

The booming market for Electric Vehicles (EVs) presents some unique challenges to the supply chain. Reliable and reusable EV battery packaging is needed to build and service the expected 125 million EVs on the road by 2030.1 Not only must new large-format batteries be shipped to automotive manufacturers and EV repair centers, but a sustainable plan for end-of-life transport is also essential to safely complete the lifecycle of EV batteries and components.

The booming market for Electric Vehicles (EVs) presents some unique challenges to the supply chain. Reliable and reusable EV battery packaging is needed to build and service the expected 125 million EVs on the road by 2030.1 Not only must new large-format batteries be shipped to automotive manufacturers and EV repair centers, but a sustainable plan for end-of-life transport is also essential to safely complete the lifecycle of EV batteries and components.

Meeting the Challenges of the EV Battery Supply Chain

There are many advantages supporting the widespread adoption of EVs that will ultimately drive the need for electric vehicle battery solutions which withstand the rigors of transport:

- Electric vehicles reduce reliance on fossil fuels for daily driving.

- EVs produce less CO2 and other emissions that contribute to climate concerns.

- Electric vehicles produce less smog and fumes that impact local air quality and human health.

- EVs can be used to support the reliability of the electric grid.

To realize these important benefits of increasing EV adoption, the challenges of EV transport must be solved. EV battery packaging that works for new, used, and end-of-life returns is already available from Endural, with sturdy purpose-built EV battery covers and cases that meet the specifications of EV automotive manufacturers.

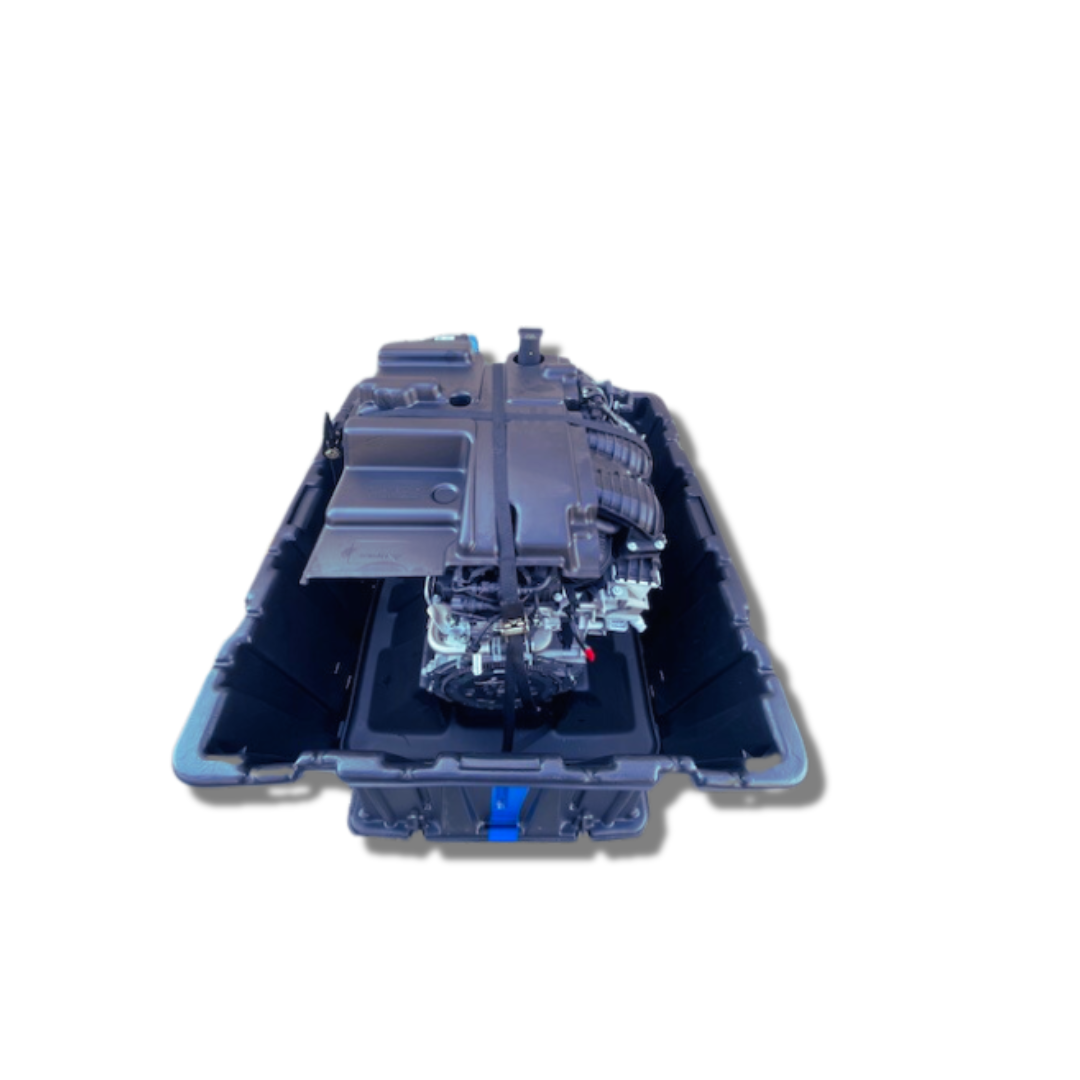

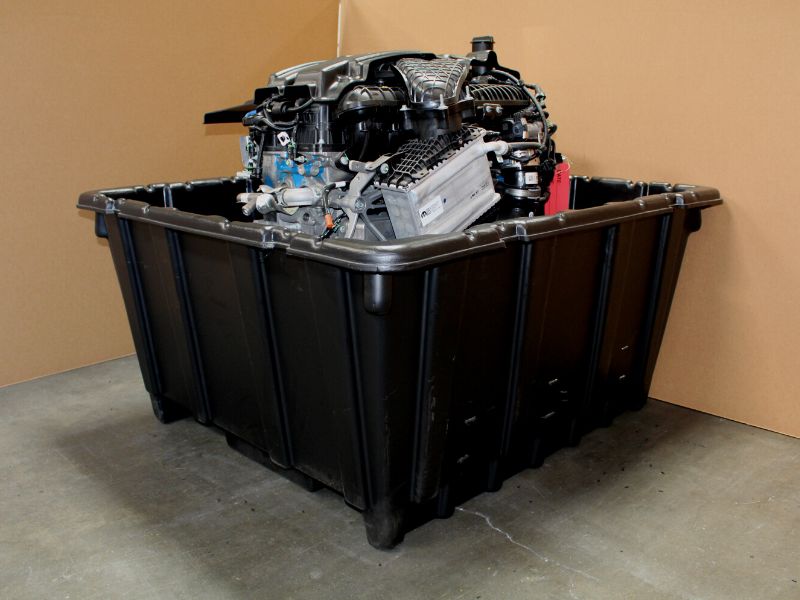

Transporting the components and cellular module assemblies (CMAs) that are used for EVs is regulated to protect the safety of workers and the environment. Endural’s line of HMWPE battery cases make up a compliant and sustainable solution to these supply chain challenges.

What Makes EV Battery and Component Transport So Challenging?

Electric vehicle batteries and components are challenging to ship because of their complex electronic and chemical properties. Some of the reasons to use an industry-specific shipping container include:

Electric vehicle batteries and components are challenging to ship because of their complex electronic and chemical properties. Some of the reasons to use an industry-specific shipping container include:

- EV batteries are classified as hazardous materials.

- EV batteries pose a significant risk of fire.

- Hazmat regulations apply to EV battery packaging and shipping.

- Workers handling EV battery components and products require special training and equipment.

- The size and weight of EV batteries requires special handling.

- Each country and some localities have specific shipping regulations for EV batteries.

- Every company involved in the shipping and transport of EV batteries and components needs to be aligned on process, equipment, and transportation requirements.

- EV battery packaging must protect the battery during transport and contain leaks if damage occurs.

Endural’s Electric Vehicle Battery Solutions

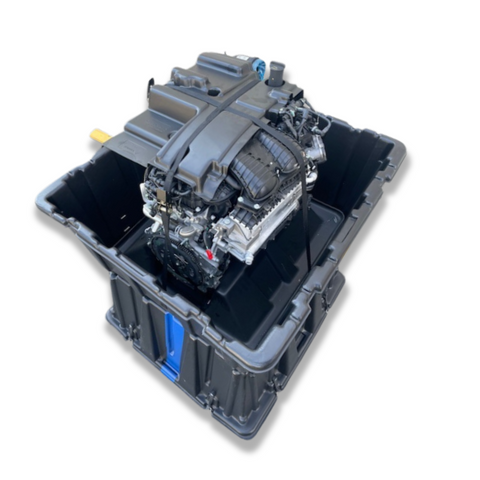

Endural is a trusted name in the automotive industry, providing a standard line and custom built HMWPE cases for transmissions, engines, axels, and more. Protecting batteries and parts during EV transport is the next evolution in our line of high quality, reusable, and recyclable transportation cases and material handling containers.

Using thermoformed polyethylene, which is impervious to most chemicals, solvents, oils, and extreme temperatures, Endural builds compliant hybrid EV battery transportation cases for top EV manufacturers, including Honda and Toyota. Your business can benefit from the same quality shipping containers for repair, replacement, and end-of-life returns. If Endural does not make the container you need, it can be custom made in a repeatable process for your line of products.

Not only do these EV transport containers meet the needs of a single shipment, but they can be used over and over again, for economic and environmental sustainability. When an Endural case meets its end of life, it is 100% recyclable and can be used to make other HMWPE products.

Features of Endural EV Transport Containers

Safety, security, and sustainability are the prime advantages of choosing Endural’s HMWPE shipping containers for electric vehicle batteries and components. All of our designs feature:

- Enhanced protection from physical forces and external impact

- Static reducing materials for electronic components and integrated circuits or chargers

- Resistance to temperature fluctuations without decreased protection of the contents

- Lined and leak resistant to prevent spills or dangerous chemical interactions

- Cost-effective as a reusable investment, with some Endural shipping containers still in use after 10 years

- Compliant with your industry regulations, our containers meet or exceed the requirements of transportation and safety regulations

Working with the EV Industry for Better Supply Chain Solutions

As transportation goes electric, there are many exciting opportunities in this growing industry. Governments and policy makers are updating their requirements for safe transport of materials and components for these vehicles, but even more innovation comes from the private sectors that are stepping up to meet the needs of EV owners and manufacturers.

Does your business ship or transport EV components or batteries for sales or service? Do you recycle the valuable components when an EV reaches end of life? If we don’t already stock the reusable and durable shipping containers and material handling containers you need, call the experts at Endural to discuss your special needs.

Our team will discuss and detail exactly how a custom plastic container is designed and manufactured. When you are sure it will meet your specifications, give us the go-ahead to create prototypes for your inspection and provide change requests or feedback. When your design is perfect for its intended purpose, give us the go-ahead to start production.

Using antiquated and unsustainable transport containers for EV purposes works against the environmental goals they promote. Move ahead with the technology and learn more about HMWPE reusable EV battery cases from Endural today.

Source: