The Advantages of Endural’s Reusable Transportation Cases over Cardboard-Based Alternatives

Modern supply chains are demanding and consume considerable resources in packaging and material handling supplies. Manufacturers are continually challenged to implement cost-effective strategies that protect the bottom line while meeting customer and corporate expectations for sustainability and greener solutions for reusable transport packaging and material handling containers.

Endural’s Reusable Plastic Containers Have Big Advantages

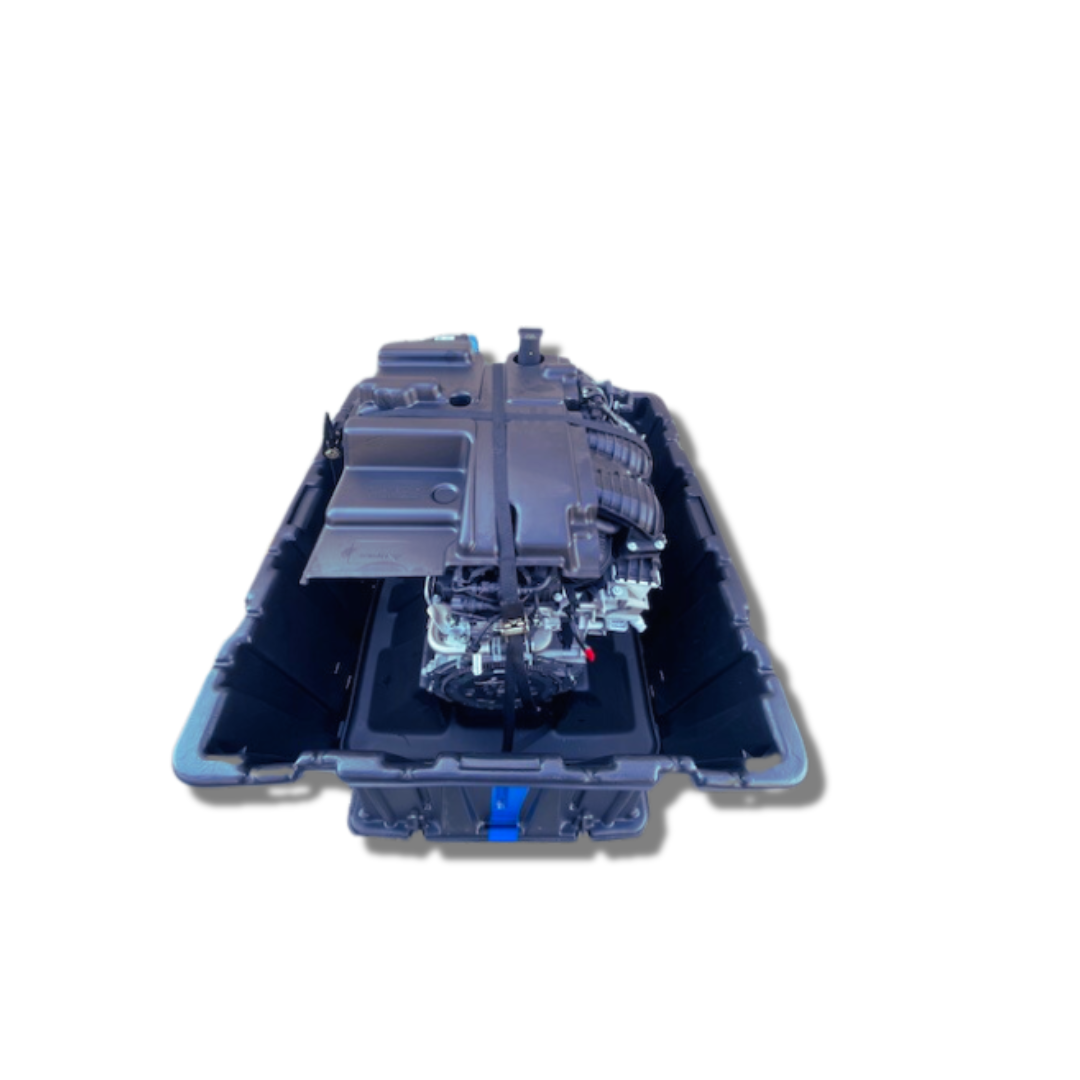

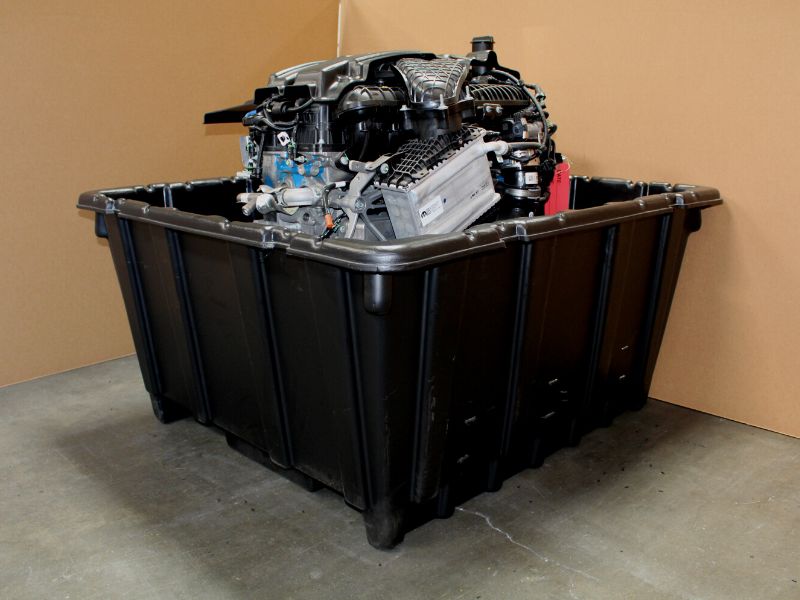

Reusable transport packaging and plastic engine shipping crates not only improve the speed of packing and handling but protect parts from damage and are more cost-effective than disposable containers. For industries including automotive, electronics, and medical equipment, reusable plastic containers offer many advantages over cardboard and single-use crates and wraps.

Reusable transport packaging and plastic engine shipping crates not only improve the speed of packing and handling but protect parts from damage and are more cost-effective than disposable containers. For industries including automotive, electronics, and medical equipment, reusable plastic containers offer many advantages over cardboard and single-use crates and wraps.

Unpacking the Problems with Cardboard Transport Containers

While cardboard alternatives are initially cheaper, there are a number of issues with single use transport and material handling containers that can directly impact profitability:

- A reusable HDPE container can be used hundreds of times.

- Cardboard containers are prone to crushing, puncture, and leakage during transport or storage.

- Reusable transport containers made of HDPE plastic can be recycled over and over again, and HDPE is more sought after as a recycled material than cardboard.

- Cardboard containers and wood pallets present health and safety risks to employees and customers due to dust, splinters, and staples. Reusable plastic containers are safer to handle.

- Using disposable packing materials does nothing to further your company’s green reputation and pushes the burden of packing material disposal downstream to your customers.

- There is no economic value to using disposable packaging, while purpose-built HDPE containers are valuable to be returned to the shipping company for reuse or recycling.

The Advantages of Endural’s Reusable Transportation Cases

As more and more industries make the transition to reusable transport packaging and material handling containers, the advantages of Endural’s HDPE transportation cases have become well established. These innovative solutions are made with custom molded inserts that fit securely inside reusable cases designed to better protect the contents and prevent leaks.

As more and more industries make the transition to reusable transport packaging and material handling containers, the advantages of Endural’s HDPE transportation cases have become well established. These innovative solutions are made with custom molded inserts that fit securely inside reusable cases designed to better protect the contents and prevent leaks.

Predictability and Profitability

Disposable and single use packaging for shipments consumes resources that are lost to your business. Prices on these materials are constantly rising, and your shipping costs become variable. By purchasing reusable shipping cases with molded liners to fit the products you ship, the investment quickly pays for itself and starts saving you money on more predictable shipping costs and reliable core returns.

Efficiency and Versatility

Large parts being shipped in disposable materials require employee time and effort to assemble cardboard cases and wrap them securely for transport. They may need a custom built wood case or pallet. All of these materials will need to be recycled or disposed of at their destination. Endural’s unique design is versatile, with custom inserts that can be redesigned to fit new products or design changes while the outer protective case stays in use.

Employee and Customer Safety

Cardboard transport packaging exposes your employees and workers at the destination to dust, sharp staples, leaking fluids, and additional work to cut straps and boxes. Endural’s reusable HDPE cases are designed for safe lifting and moving without handles. The cases require no sharp tools to open. Once the part is unpacked, the entire container can be returned to the manufacturer empty or with a core for remanufacture included.

Environmental Sustainability

The manufacturing supply chain consumes a tremendous amount of natural resources in single-use shipping materials each year, and most eventually wind up in a landfill. Studies show that switching to reusable transport packaging can drastically reduce the environmental impact of shipping parts and materials by:1

- Reducing solid waste in landfills by as much as 86% over single use packaging

- Lowering CO2 greenhouse gas emissions 60% by eliminating the need to manufacture more single use packaging

- Using 64% less energy to manufacture and recycle reusable containers over their lifespan than single-use cardboard alternatives

- Consuming 80% less water than single-use packaging options over their lifespans, HDPE shipping cases remain environmentally friendly during their manufacture and eventual recycling and disposal

- Supporting a circular economy where reusable HDPE transport cases have a long useful life and are used many times before being recycled into new cases and inserts

Durability and Damage Prevention

HDPE plastic cases designed for shipping your products are more durable and higher quality than cardboard or single use plastic alternatives. These sturdy containers stand up to the rigors of transportation and better protect the quality of your products. Endural cases are approved by major automotive manufacturers and EV battery suppliers because of the sturdy construction that protects the part from damage and the environment from dangerous chemicals and fluids.

Making the Switch to Reusable Transport Packaging

Your business can start reaping the benefits of reusable plastic containers made of high-quality HDPE plastic right now with Endural’s durable transport containers. Our cases are 100% recyclable and some of them have been in constant use for more than 10 years. The customizable inserts can be form-fitted to your products and returned for reuse for years to come. Make the right investment for a greener, more profitable shipping model and contact us today to learn more about the advantages of Endural products for your business.

Source: